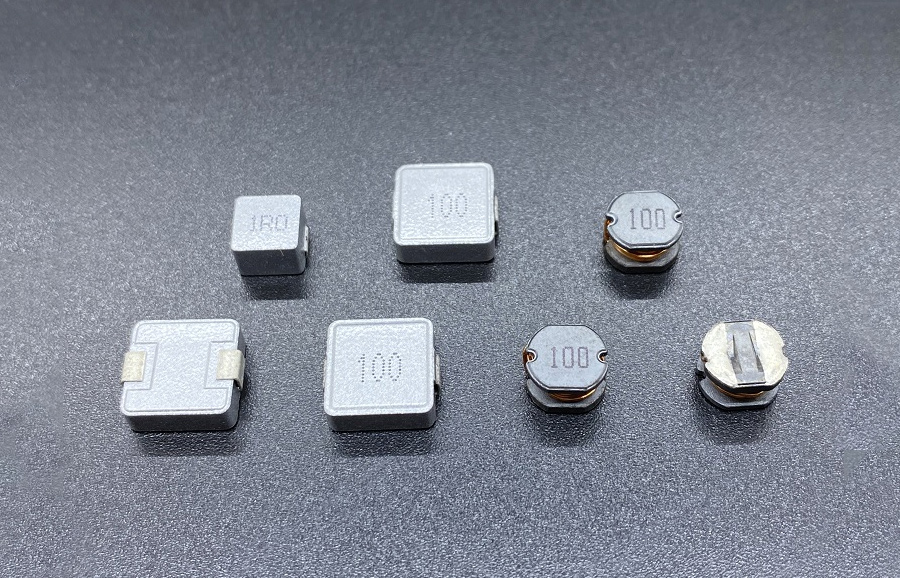

Which Is More Advantageous between Molding Powder Inductor and Wire Wound SMD Power Inductor

The materials and production processes are different. The integrated inductor is made by die-casting the base of the winding body embedded in metal magnetic powder, and the surface packaging pin is the lead out pin of the winding body directly formed on the surface of the base body. However, for ordinary power chip inductors, copper wire is wound around the magnetic core and then sealant is applied.

1.The shielding effect varies. Integrated inductor has better shielding effect.

2.The current varies in magnitude. The current of the integrated inductor is higher.

3.Prices vary. Compared with ordinary power chip inductors, the cost of integrated inductors is higher due to its material and process, which is higher in price than ordinary power chip inductors.